Trauma Implants: Considerations, quality, manufacturing and expertise

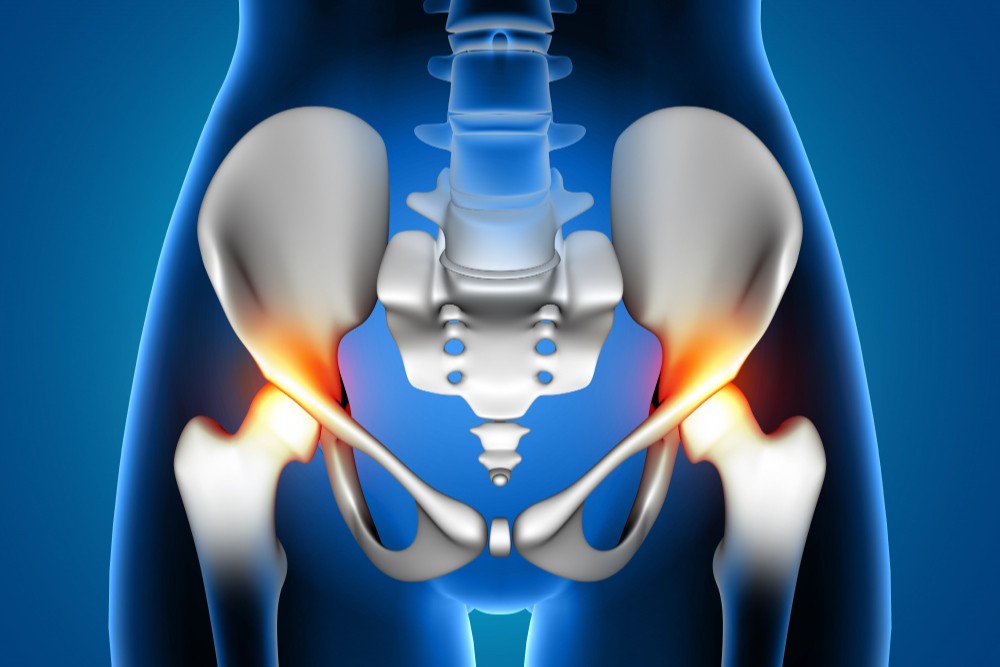

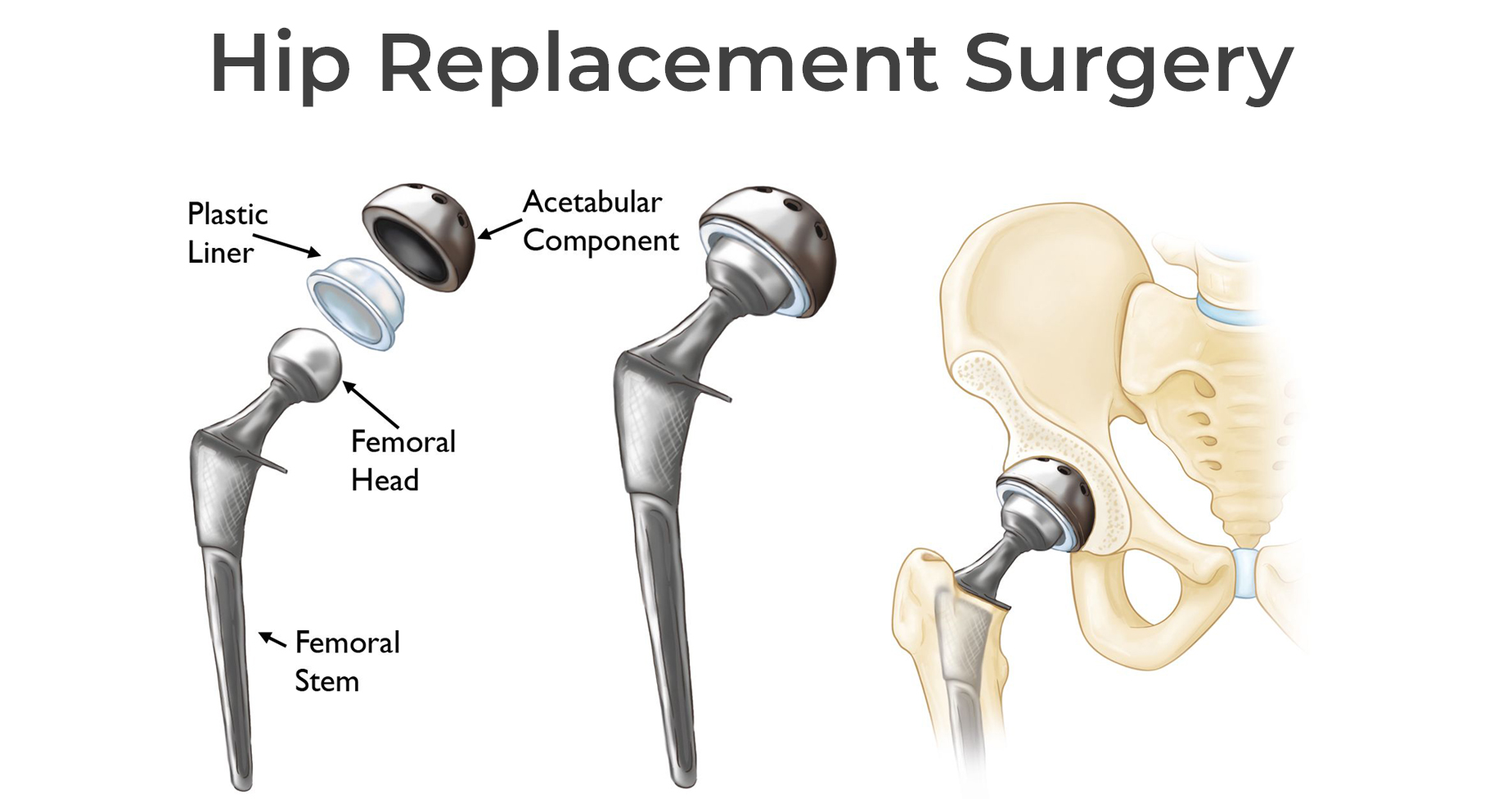

An orthopaedic implant refers to a medical device that is made to replace or fix a missing joint or bone or to support a bone that has been damaged by accident. Orthopaedic implants are also known as trauma implants as mainly they are required in time of accidents. These surgical implants are mainly made up of titanium alloys and stainless steel to provide proper strength to the bones. They also come with a plastic coating which acts as artificial cartilage.

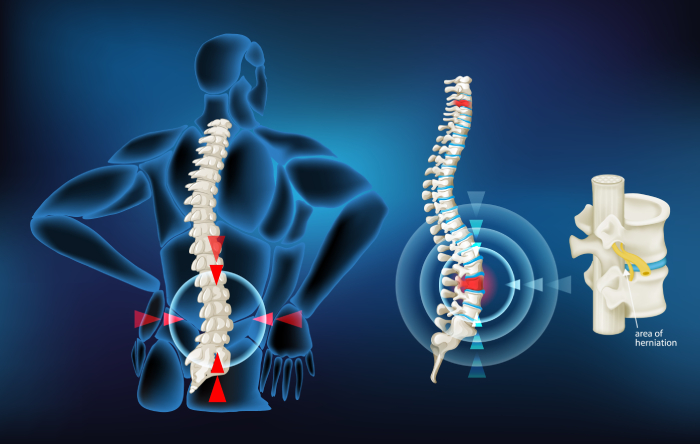

What is Internal Fixation?

In Orthopaedics, internal fixation is known to be a fixing method or an operation that involves the implementation of these orthopaedic implants for the purpose of repairing a bone or joining two or more fragments of bones surgically. While performing this surgery through this process, the fragmented bones are first reduced into their normal alignments, and then they are made to stay together with the help of various internal trauma implants as plates, nails, screws, wires and pins. These internal fixators are known as trauma implants.

What is the ideal trauma implant material?

Any material which is considered to be ideal for the making of trauma implants could be described as having the following characteristics:

- Chemically inert.

- Absolutely biocompatible.

- Great strength.

- High fatigue resistance.

- Low elastic modulus.

- Absolutely corrosion proof.

- Good wear resistance.

- Inexpensive

Materials currently used to make trauma implants.

- Metals - Different types of metals are used to make trauma implants which include surgical grade stainless steel, cobalt-chromium alloys and pure commercial Titanium for Titanium alloys. Most of the time, stainless steel is used for implants that are non-permanent in nature search as internal fixation devices. The reason behind this is that stainless steel has a poor fatigue strength and liability to undergo plastic deformation.

- Polymers - A large number of monomers are joined with the help of chemical reactions to form polymers. Organic Polymers are different as they have monomers to be an organic molecule with the central carbon atom. The most popularly used polymer in the production of trauma implants is Ultra high molecular weight polythene for high-density polythene. It is clearly evident that polythene is the best material that can be used for articulating with metal and ceramics.

- Ceramics - Different types of ceramics are used to make Orthopaedic implants which include Aluminium oxide and Calcium phosphate. These ceramics are known to be very resistant to compression but do not have enough strength under tension and shear and brittle. Aluminium oxide ceramics are formed by a process called hot pressing, in which simultaneous application of pressure and temperature is used to make a powder. Later the final product is made with high density, small grain size and good mechanical properties. Ceramics have high modulus compared to human bones.

For permanent implants, materials like Titanium and Cobalt-based alloys are largely used. These alloys are known to be corrosion-resistant, but in spite of this fact, it is observed that ion release is a significant concern as metals like chromium, Nickel and Cobalt are known carcinogens. On the other hand, Titanium is widely used to make these implants and is highly biocompatible.

However, there are also several concerns with these polymers. One of the biggest problems with polymer is that it is very slow and temperature dependent, and the deformation that it suffers under load is commonly known as creep. Another major concern regarding polythene is that it is the progressive wear. Although with time, implantation of cement list devices is increasing, but the use of self-curing bone cement, which is nothing but acrylic polymer, still remains widespread.

Conclusion

In the case of Trauma Implants: Considerations, quality, manufacturing & expertise are the most important things to be considered as these are the things that will result in a successful operation.